Innovations in Injection Moulding: 3D Printing and Industry Trends

Innovations in Injection Moulding: 3D Printing and Industry Trends

Introduction

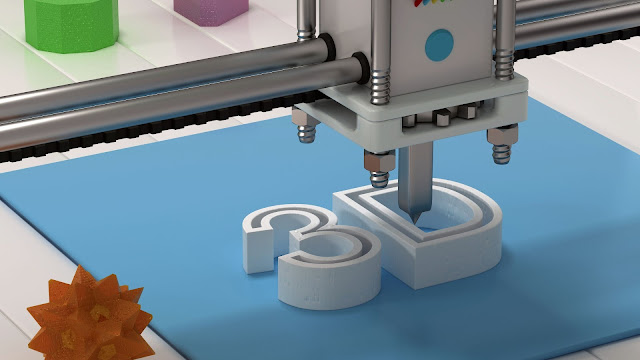

The world of injection moulding is continuously evolving, with technological advancements and innovative solutions driving the industry forward. Among these exciting developments, 3D printing has emerged as a game-changer, revolutionizing the way plastic components are manufactured. In this blog, we will explore the fascinating innovations in injection moulding, with a specific focus on 3D printing, and discuss the latest industry trends that are shaping the future of manufacturing.

1. The Rise of 3D Printing in Injection Moulding

Traditional injection moulding has long been the go-to method for mass-producing plastic components with precision and efficiency. However, 3D printing, also known as additive manufacturing, has rapidly gained traction as a complementary and even alternative technique. Unlike conventional moulding, 3D printing builds parts layer by layer from digital models, allowing for complex geometries and rapid prototyping. This innovative approach eliminates the need for costly moulds and significantly reduces lead times, making it ideal for low-volume production runs and custom designs.

3D printing's benefits extend beyond just prototyping. The technology's versatility has led to its adoption in various industries, including aerospace, automotive, healthcare, and consumer goods. As materials and processes improve, 3D-printed parts can even rival the strength and durability of traditionally moulded components, opening up new possibilities in manufacturing.

2. Advantages of 3D Printing in Injection Moulding

a. Design Freedom: One of the most significant advantages of 3D printing in injection moulding is the freedom it offers in design. Complex geometries, hollow structures, and lattice infills that were once difficult or impossible to achieve with traditional moulding are now attainable. Designers can iterate quickly and experiment with various designs, accelerating the product development process.

b. Reduced Tooling Costs: Traditional injection moulding requires expensive tooling, especially for intricate parts. 3D printing eliminates this cost-intensive step, as parts are directly produced from digital files. This reduction in tooling expenses makes 3D printing a cost-effective solution for small production runs and prototypes.

c. Rapid Prototyping: 3D printing enables rapid prototyping, allowing designers to visualize and test their concepts before committing to mass production. This agile approach not only saves time but also minimizes material waste.

d. Customization: With 3D printing, manufacturers can easily customize products to meet individual customer needs. This level of personalization has become increasingly important in today's market, where consumers seek tailored solutions.

3. Industry Trends Shaping the Future of Injection Moulding

a. Sustainability and Eco-Friendly Solutions: In response to growing environmental concerns, sustainability has become a top priority in the manufacturing industry. Brands like Rutland Plastics are spearheading eco-friendly initiatives by adopting biodegradable and recycled materials for injection moulding. Additionally, energy-efficient manufacturing processes and reduced material waste are central to their sustainability efforts.

b. Industry 4.0 and Smart Manufacturing: The integration of advanced technologies, such as IoT sensors and data analytics, has given rise to Industry 4.0. Smart manufacturing practices are enhancing efficiency, optimizing production processes, and minimizing downtime through real-time monitoring and predictive maintenance.

c. Robotics and Automation: Automation has become a defining trend in injection moulding, enhancing precision, speed, and consistency. Collaborative robots, or cobots, are working alongside human operators, streamlining production and ensuring safer working environments.

d. Material Innovations: The development of new materials with enhanced properties is pushing the boundaries of injection moulding. Lightweight and high-performance materials are increasingly sought after in industries like automotive and aerospace, where reducing weight is critical for fuel efficiency and performance.

Conclusion

Innovation in injection moulding is driven by technological advancements and a commitment to sustainability. The integration of 3D printing has revolutionized the industry, offering design freedom, cost-effectiveness, and rapid prototyping capabilities. As sustainability gains prominence, manufacturers like Rutland Plastics are embracing eco-friendly practices and material innovations to meet the demands of a more conscious consumer base. Coupled with the transformative impact of Industry 4.0 and automation, injection moulding is poised to remain a dynamic and essential component of modern manufacturing.

.jpg)

Comments

Post a Comment