What Is Electrofusion and How Does It Work?

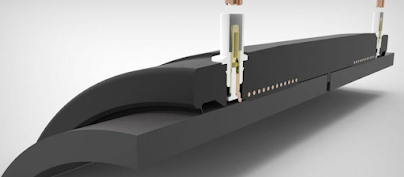

It is a popular welding method used to join high and medium-density polyethene piping. It can also be found on various plastic-based pipes. Electrofusion welds parts together using special fittings with built-in electric heating components.

The ends of the pipes that will be welded are cleansed to begin the operation. They're then inserted into the electrofusion fitting, and voltage is supplied to the connection to fuse it—the heating coils melt the pipe wall and the fitting on the outside. A strong homogenous joint is formed after the assembly cools. If done correctly, the connection will be as robust as the original pipe and will be able to sustain all of the loads required for standard installation.

Equipment:

Electrofusion welding necessitates the use of specific equipment. Before welding, these items should be prepared. The welding process will not be disrupted in this way. The electrofusion welding equipment includes a scraping tool, measuring instrument, mark pen, cutting tool, electrofusion welding machine, and clamps.

Welding Machine:

The electrofusion welding machine requires the use of a generator. In order to run the generator, it must be fully fueled. The electrofusion fittings are connected to the generator once connected to the welding machine. Welding is done, and voltage is given. The precise heating time can be found on the fittings' barcodes. When applying heat, barcodes should be considered. This method allows for safe welding. The electrofusion machine cables are withdrawn after the fittings have been heated.

Effectiveness of Electrofusion:

Electrofusion's efficacy depends on careful preparation of the jointing surfaces and ensuring that the surfaces to be fused maintain enough contact during the welding and cooling cycles. Before fusing, the pipe's surfaces that are to be connected must be scraped to remove the surface oxidation layer. During the fusion cycle, pipe clamps or other approved restraining, aligning and rerounding the pipes should be utilised.

Benefits of Electrofusion:

1. User-friendly:

Electrofusion is a high-efficiency welding technique that combines customised fittings with built-in electric heating components to make the system homogeneous. Before being left to cool, the welding equipment connects to the fitting and automatically determines the welding time. This method is ideal for on-the-job joints or those in restricted spaces.

2. Durable:

The automated pipe joining method is significantly more accessible, faster, and reduces 'human' errors. The inside of the tube remains smooth because the weld is created on the outside, adding to the overall network's flow quality and preventing scale and incrustation, which can cause significant difficulties at joints.

3. Consistency:

Most specialists agree that electrofusion is a reliable approach for joining pipes. You can count on electrofusion to deliver high-quality, high-performance welds with long-term serviceability.

Conclusion:

The cost of electrofusion fittings used to connect HDPE pipes varies. The fittings are formed to match the flooring where the pipes are situated. A variety of firms manufacture fittings. When selecting a firm, it is critical to consider the quality of its product. It is feasible to work without incident with a reputable organization. Quality and long-lasting electrofusion fittings are cost-effective.

.jpg)

Comments

Post a Comment